Glass bottle printing process

Published on:

2022-09-15

To help you better understand the printing process requirements of glass bottles

Glass bottle printing process

Silk screen printing methods

1. It can be printed on a silk screen. Silk screen printing belongs to stencil printing, which is known as the four major printing methods together with lithographic printing, letterpress printing, and rotogravure printing.

Stencil printing includes transcription, perforated pattern, spray pattern, and screen printing, etc.

The principle of stencil printing: during printing, the printing plate(a paper stencil or other plate base to make holes through which the ink can pass) will have a certain pressure to transfer ink through the holes of the stencil to the substrate (paper, ceramics, etc.), cause images or text are formed on the substrate.

2. It can be printed by roasting. Roasting is another way of pattern printing on glass bottles, that is, after the bottle body is decorated with patterns, it is put into the oven for firing, and finally, the patterns or characters are firmly attached to the glaze of the porcelain.

The ink is printed on the glass surface, and then the curing measures of the ink are used to make the printed pattern firm and durable.

The process is as follows: stretching the screen → sizing → drying → printing → developing → drying → flat glass → cutting → edging → cleaning and drying → printing and sintering

Selection of glass for printing: The glass should be cut into regular or irregular shapes according to the user's requirements, then be chamfered and ground, washed, and dried for use. Note that there should be no traces of water on the glass surface.

Selection of screen: The glass screen printing plate is the same as the general screen printing plate, using synthetic fiber screen, stainless steel screen and natural fiber screen. When printing general pigments, the above-mentioned meshes can be used, and cheap a synthetic fiber meshes are mostly used. When used as gold and silver decorations, stainless steel meshes cannot be selected. Mesh specifications generally use 270 to 300 mesh.

3. Selection of screen frame: The current regular and less deformed screen frame is an aluminum alloy screen frame, its size should be larger than the pattern, and the outer edge of the pattern should be between 70 and 100mm from the screen frame. The strength of the screen frame is very important, The key is that the rigidity in the horizontal direction is sufficient.

4. Selection of stretch net: The combination of the wire mesh and the mesh frame is stretch mesh. There are many ways to stretch the net, which can be manual, motorized, and pneumatic. At present, the more advanced one is the pneumatic stretcher, which can stretch the high-quality screen. The requirements for stretching the net are that the tension should be uniform, the warp and weft lines of the net should be kept vertical, and the glue should be firm and not slack.

Cold stamping is a technique in which the hot stamping foil is transferred to the printing material using a printing plate and a UV-curable adhesive. Compared with traditional hot stamping, the whole process does not need heating and has no special metal hot stamping plate, so it can save a lot of energy, and meets the requirements of green environmental protection. Cold stamping technology can be divided into dry lamination type and wet lamination type according to the process.

1. Dry lamination type

The coated UV adhesive is cured before hot stamping. Its main process steps are as follows:

1) Printing UV adhesives on web substrates;

2) Cure UⅤ adhesive;

3) The hot stamping foil is compounded with the printing material by a pressure roller;

4) Peel off the excess hot stamping foil from the printing material, and transfer the hot stamping foil to the printing material only on the part coated with the adhesive to obtain the desired hot stamping graphics.

2. Wet lamination type

After the UV adhesive is applied, the UV adhesive is first stamped and then cured. The main process steps are as follows:

1) Printing free radical UV adhesives on web substrates.

2) Laminate composite cold stamping foil on the substrate.

3) Curing the free-radical UV adhesive. Since the adhesive is sandwiched between the cold stamping foil and the printing material at this time, the UV light must pass through the stamping foil to reach the adhesive layer.

4) Peel off the hot stamping foil from the printing material, and form the hot stamping image on the printing material.

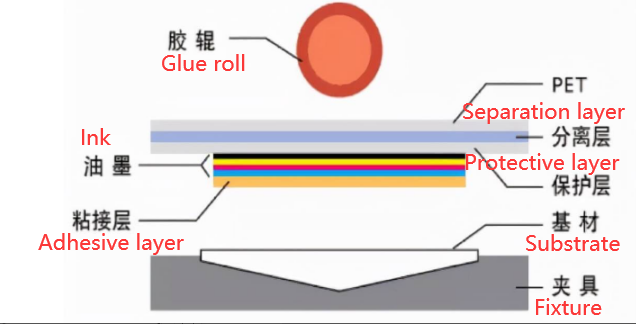

Thermal transfer mode is a technical method of printing patterns and a glue on a heat-resistant film, and adhering the pattern (ink layer) and glue layer to the glass bottle by heat and pressure. This process is mostly used on plastic and paper, and less on glass bottles.

Process flow: 1. Color draft; 2. Film printing; 3. Thermal transfer; 4. Baking.

The thermal transfer film is generally divided into five layers, the surface PET film layer is used as the carrier, and the separation layer is suitable for falling off when heated. The protective layer plays the role of protecting the ink layer, the ink layer is pattern printing, and the adhesive layer is the adhesion layer.

Since the multi-color pattern can be drawn at one time in the film printing stage, the existing pattern can be transferred to the glass bottle at one time during the transfer operation on the glass bottle. Compared with the cumbersome set of multi-color screen printing, it can greatly shorten the work of the printing and reduce the loss of materials caused by printing errors. At present, labor costs are constantly rising, and customers have high-quality requirements for accurate positioning, so the advantages of thermal transfer on multi-color manuscripts are very obvious.

In addition, in the film printing stage, CMYK printing is routinely used, and spot color printing can also be carried out according to customer requirements. The effect of thermal transfer printing is more realistic, the color reproduction is high, and gradient colors can be realized. Due to the relationship between heat and baking of the image, the color of the finished image will be firmer than that of water transfer, and it will not be prone to fading. It has good properties such as corrosion resistance, aging resistance, wear resistance, and high-temperature resistance.

Relevant news

undefined

Shantou Xinrong Co., Ltd.

COPYRIGHT © 2022 SHANTOU XINRONG CO., LTD.(汕头市鑫荣贸易有限公司) 粤ICP备2022040726号 TECHNICAL SUPPORT BY 300.CN Privacy Agreement

COPYRIGHT © 2022 SHANTOU XINRONG CO., LTD. (汕头市鑫荣贸易有限公司)

粤ICP备2022040726号

TECHNICAL SUPPORT BY 300.CN Privacy Agreement

Product inquiry