Plastic bottles cosmetic plastic bottle packaging – Everything you need to know about

Published on:

2022-06-10

With this in mind,let's get ready to explore potential Cosmetic plastic bottle packaging goals with us,and understanding variouse plastic types for product manufacturing has tons of advantages.

Plastic bottles – Everything you need to know about

Plastic bottles make our life so easier. They are super lightweight and simple to hold and they are also strong and hard to break.

A plastic bottle is an ideal way to contain and carry several kinds of liquids, from water plastic bottles and soft drinks to oil to household cleaners to cosmetics and baby formula.

History of plastic bottles

Uses of plastic starting in the late 1800s to its expected developments by 2022 and beyond and several fascinating innovations have taken place. Such products are glass bottles, plastic jars, plastic spray bottles, juice bottles, plastic bottle bird feeders, and plastic bottle greenhouses, have come a long way over the times and have huge potential to make advancements in the coming times.

Keep reading the blog to learn more about the history of plastic bottles:

Plastic was invented in the nineteenth century and was originally used to replace common materials. In the 21st century, this once celebrated creation has become almost like a disease that has spread to a huge amount of commodities sold today, including soft drinks.

It took long for plastic to become a well-known domestic product and now we’ve reached our max plastic consumption; homeowners are struggling to rid their lives of plastic to go green.

Alexander Parkes created the first manmade plastic in 1862, which was derived from cellulose and named Parkesine. Later in the nineteeth century, John Wesley Hyatt created celluloid from a combination of shredded tissue paper, sulfuric acid, and nitric acid to make 1st thermoplastic, which was used and is still used currently for photographic film.

The next milestone in resins comes in 1907 when NY chemist Leo Baekeland invented Bakelight the military found it super helpful in the production of weapons it was also used for radio cups, buttons, radios, and false gums.

By the 40s, acrylic, nylon, SBR, neoprene, and polyethylene were becoming huge widespread. Between1940 to 1945, the demand for plastic in the US grew largely and tripled in production due to the war, oversight, public funding, and versatility of the materials.

All of the discoveries and inventions gave way to different sorts of plastic, including PVC (polyvinyl chloride) or vinyl, Teflon, polyvinylidene chloride, high-density polyethylene (HDPE), polyethylene terephthalate (PET), polypropylene (PP), low-density polyethylene (LDPE), and polystyrene (PS).

The first bottled soda water in the US was made in 1835, plastic bottles for soda were not in use until 1970 and the first PET plastic bottle was made 3 years later.

In July 2010, the 1zs ship made from recycled plastic bottles was constructed. Since plastic bottle craft and plastic bottle recycling our society has taken full benefit of this material and created several purposes for it besides soda bottles.

Raw Materials of Plastic Bottles

Plastic goes through a manufacturing procedure to end up as bottles for liquid substances such as soda, juice, oil, shampoo, and milk and fry dry products such as nutritional supplements and medications.

In its raw state, it is made up of several organic polymers, including ethylene and polyethylene. In a soft state, it can be molded into the desired form and then cast into a solid-state.

These are made of polymers, which are chemically bonded to make materials such as polystyrene and polyethylene. The different materials of plastic bottles include PET and high density polyethylene. If you’ve a plastic bottle check the base of it for the resin identification code to find out what is made of.

Polyethylene Terephthalate

A bottle made of Polyethylene Terephthalate has the resin identification code 1. Also known as PETE, PET, or polyester, it’s often used for soft drinks, water, and food items because it’s super light and strong.

Like most plastic bottles, PET bottles are made from petroleum hydrocarbons, formed as a reaction between ethylene glycol, a colorless viscous liquid, and terephthalic acid. During the production, PET polymerizes from long molecular chains.

High-Density Polyethylene (HDPE)

The resin identification code 2 denotes HDPE. It’s economical and yields and super-efficient water barrier, making it the most widely used material for plastic bottles. It’s made from petroleum, a naturally occurring liquid found in geological formations below the earth.

It’s resistant to several solvents and has a high density to strength ratio, creating it the right plastic for reusable and recyclable plastic bottles. For plastic bottle recycling near me, it is also used to make pipes, fireworks, lumber, and plastic bags.

Low-Density Polyethylene (LDPE)

It has the same makeup as HDPE but is more translucent, and very less chemically resistant. LDPE has the resin identification code 4, is created from the monomer ethylene and is most commonly used to make bags, but it can also be found in dispensing bottles, detergent, and squeezable bottles like mustard and honey.

Polystyrene (PS)

It is a synthetic aromatic polymer created from monomer styrene. It might come solid or foamed and has resin identification 6. As a rigid plastic with a super moisture barrier and low thermal conductivity, PS is often utilized to make plastic bottles for dry products, such as cosmetics, vitamins, and aspirin.

Advantages of plastic bottles

Rugged and Safe

Unlike glass jars or bottles, plastic bottles are rugged and super resilient, they do not shatter into sharp pieces when dropped, making packaging and products safe to handle. Because plastics are polymers – long molecules made by connecting several short ones combine – they’ve useful physical elements such as resistance and toughness to chemicals. The similar resilience makes plastic bottles unlikely to burst or leak, protecting the contents and exterior shipping cartons.

Shapes and Colors

Plastic materials are super easy to mold into a huge range of designs and plastic bottles manufacturer and plastic bottle suppliers can easily transfer them into any shape, improving their appearance and utility. For instance, companies incorporate integrated handles, measurement marks, and pouring lips into a few types of bottles.

In addition, it can range from super clear to any color or shade, whether clear or opaque, making products and brands simple to identify by sight. Plastic bottles need no paint, the coloring material is mixed into the resin, so it never rubs sun or washes off.

Energy Savings

Plastic bottles are super light in weight than user glass containers, reducing costs and energy needed to ship products. Because these are soft and have relatively low melting points, they take less energy to craft than glass.

A Recyclable Material

After 1st use, PET and other types of bottles are easily recycled into several types of secondary products, including pillow stuffing, carpet fibers, tote bags, and strapping materials. Some soft drink bottles and non-food jars also use rekeyed plastic. The lightweight of bottles reduced the costs of transporting materials to recycling centers.

Process of Recycling Plastic

Recycling takes several steps. 1st, the bottles have to collect from businesses, homes, and other sites. Then each bottle must be separated from glass, metal, and other things that people put into recycling bins. The bottles are also sorted by the sort of plastic they are made from. Then, the bottles are cleaned, and removed any food particles, chemicals, or liquid.

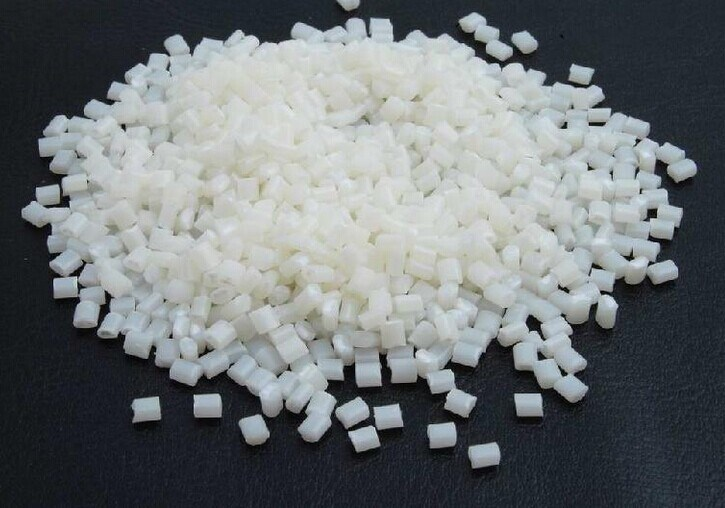

Next, all bottles are ground up and shredded into flakes. Lastly, they’re melted down and formed into little pallets, each about the size of rice grain. The pellets are bundled-up and sold to plastic bottle wholesales that can melt them and make them into several different products. There’re several plastic bottle recycling ideas out there, you just need to pick one according to your preferences.

Why put the plastic bottle on your tire?

In addition, a plastic bottle on a tire meaning is used to protect nuts or bolts from freezing, which freezes extremely strong, at very low temp. As an outcome, when a driver notices a tire cracking, he can’t simply change the tire, immediately. Most often, plastic bottles are used on tubeless tires due to their faster wear.

Accessory on tires can be seen both in winter and the other seasons of the year. There’re many reasons for carrying out such manipulations.

The most common are:

Protecting ties from intruders who went to steal them – plastic bottles are used instead of signaling. After all, buying a new tire can cost thousands of dollars.

An alternative to lost caps from stud nuts – this makes sure safety while driving. When driving, the fasteners don’t catch pedestrians in the event of a collision, they’re not able to catch on outfits and drag a person behind them.

Install bottles on the front tire studs – to identify issues with the front or rear axle. When braking the wheel during rotation, the plastic bottle crumples, specific sounds are heard when crushed. The end words are that drivers identify a breakdown.

How to Make a Bird Feeder Out of Plastic Bottle?

This is one of the simplest homemade bird feeders you can make. Main things you need is a few supplies, and you will have a lot of backyard birds flocking to your new recycled bird feeder.

Many people think about making bird feeders only in the winter season, but we enjoy making them ornaments and DIY bird feeders the entire year long. Offering the backyard birds with berries, seeds, and nuts is a joy to watch and be a part of, plus it helps the species get the nutrition they need.

Cosmetic plastic bottle packaging – a solution for products all over the world

The world of cosmetic plastic bottle packaging brings with it solutions for every product all over the world. We can be shaped plastic into bottles, jars, dispensing pumps, cosmetic packaging, and innovative ideas that can be the next huge selling product on the market.

Cosmetic plastic bottle packaging serves today’s packaging needs, from merchandising to product protection, and let’s not forget their overall part with suitability factors on our environment.

End words…

With this in mind, let's get ready to explore potential Cosmetic plastic bottle packaging goals with us, and understanding various plastic types for product manufacturing has tons of advantages.

If you get the material perfectly you can cut costs, be environmentally friendly and make your product more amazing.

Relevant news

undefined

Shantou Xinrong Co., Ltd.

COPYRIGHT © 2022 SHANTOU XINRONG CO., LTD.(汕头市鑫荣贸易有限公司) 粤ICP备2022040726号 TECHNICAL SUPPORT BY 300.CN Privacy Agreement

COPYRIGHT © 2022 SHANTOU XINRONG CO., LTD. (汕头市鑫荣贸易有限公司)

粤ICP备2022040726号

TECHNICAL SUPPORT BY 300.CN Privacy Agreement

Product inquiry